The Device Chronicle interviews Dr Marius Grathwohl, Vice President, Digital Products and Transformation, and Simon Stark, Business Development Manager on Digital Products, on digital transformation at Multivac and its membership of the Open Industry 4.0 Alliance.

In 2017, the Multivac Group started working out its digital strategy. It started with the creation of a strategy paper that outlined a mission to enable the workforce with the proper digital processes, and two other objectives for digitalization in customer-driven activities. The first involved the good alignment of new digital products and services with the traditional product portfolio consisting of machines and spare parts. The second involved initiatives to go beyond the traditional services and look at using partnerships with other like-minded vendors to develop new customer-centric services. Marius explains that Multivac being a co-founder of the Open Industry 4.0 Alliance, and active participation in the Alliance complemented the latter objective very well indeed.

Collaborative role in the production line

Simon adds that the objective of the OI4 membership is to be stronger in the “constellation with 3rd party competitors in the production line of the customer and this is good and normal, as the providers´ expertise is bundled within these services.”

All providers are running their own initiatives to develop smarter services for their customers on their own – in order to leverage the value of the data from their own machines. But the customers want to have the whole puzzle solved across the production line.

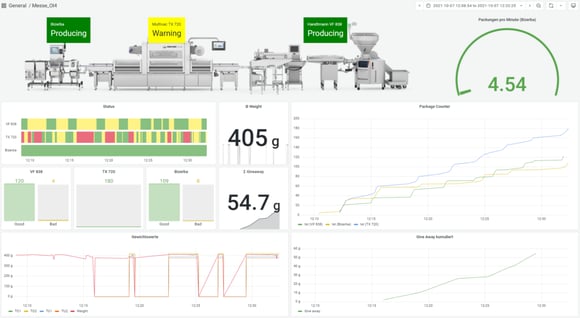

Multivac has promoted a food and beverage use case through the Open Industry 4.0 Alliance and has worked with competitor Schiwa to incorporate its meat slicing machines into Multivac’s smart services for its packaging machines so that the customer can get more value from insights from the data being generated by Schiwa slicing machines. Simon describes this collaboration with Schiwa as the starting point of collaborative customer-focused digital activities. He further explains that Multivac has also worked with Bizerba and Handtmann to build a collaborative dashboard with data points from the services of both companies. Simon says “This dashboard shows important insights from the end of the “check way” from Bizerba machines, information regarding good and bad portions at the beginning of the production line, and how many good and bad “packs” are produced by the production line thus there is greater transparency across the line.”

Decarbonisation and digitization

Multivac is also collaborating with suppliers such as Busch and Emerson Aventics on the strategic topics of carbon footprint reduction and energy efficiency. Emerson Aventics provides Multivac as a machine builder with a pressurized air consumption IoT sensor. To address the ISO 50001 compliance standard, Multivac offers a package which analyses the total consumption of its products, e.g. air, electricity, gas, film, vacuum and water consumption. The new generation of consumption monitoring also enables Multivac to provide leakage detection to their customers. Both, Emerson Aventics’ and Multivac’s involvement in the Food & Beverage industry workgroup has helped to create this joint digital discourse.

Simon explains that this is all about having a smoother integration of components within the machine and transferring the data about the performance of that component within the machine back to the supplier. “There are mutual benefits for the component supplier, machine builder and customer from this collaboration. The next generation is to transform to shared value creation with the customer as the focal point.”

Machine builder, process & Industrial IoT

Multivac provides a solid PLC device and software, and Simon highlights the fact that the evolving IoT environment is having an impact on production process equipment. He says “Safety and individual retrofits are also important considerations. The software has to be adapted to the machines, software bug fixes must be pushed out from centrally much quicker and replacing the use of USB key by field engineers. Updates for edge devices are in place, as part of the CI CD process and machine controls will be updated soon. Sensoric components within the machine also need to be analyzed. Simon adds that Multivac’s participation in the remote device management working group in the OI4 helps to guide strategy.

Marius concludes the interview by pointing out that Microsoft Azure has helped build the smart services and edge applications. He says that his group, together with corporate IT, have been thinking about how to leverage the latest technologies and concluded that they needed a cloud solutions team within central IT to realize the operation of smart services. “Now, the whole of Multivac Group can participate in the learnings from the cloud applications. We have developed serverless daughter companies.”

Power of the OI4 Alliance

Marius and Simon are both strong believers in platforms and networks and that the future of industry 4.0 is interoperability and compatibility and everything that is needed for that. Marius comments “You need to be able to mingle with other partners to be successful, so you need a digital ecosystem of industrial companies.” Simon adds, “Openness is absolutely necessary for Multivac as a machine builder and their customers.”

Visit the Open Industry 4.0 Alliance to learn more about becoming a member. Northern.tech and its OTA software updates solution Mender.io is a member of the alliance.